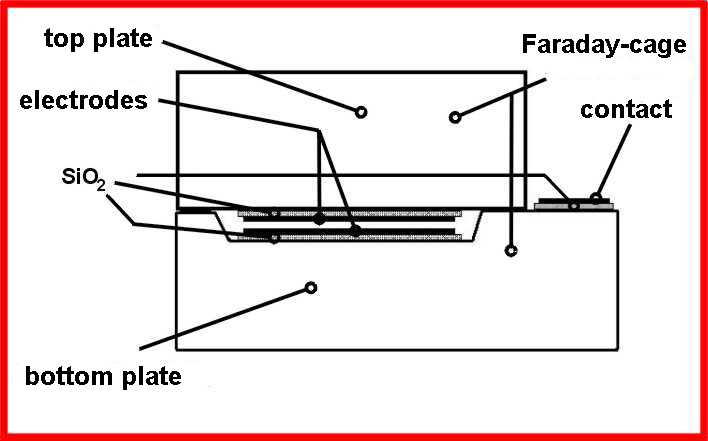

| Capacitive sensors with

integrated Faraday Cage: Are specially susceptible to stray

electric/magnetic fields and noise. While a robust

enclosure can protect the sensor it will falsify at the

same time the received signal considerably. This is not

the case with the patented Capacitive Microsensor , which

is self protected in the middle of a Faraday Cage. The sensor outlet is monocrystalline silicon, which is quite suitable for

this function due to its elastic property.

Through an etching process, a

cavity is etched inside this silicon cell to produce a

highly elastic fatigue free silicon membrane. Basically

the Sensor is built as a MOS-Sandwich

(Metal/Oxide/Semiconductor). The membrane and the base plate,

both made out of silicon, are then fused together on the

outside periphery, forming a mechanical and electrical

entity. Through an etching process, a

cavity is etched inside this silicon cell to produce a

highly elastic fatigue free silicon membrane. Basically

the Sensor is built as a MOS-Sandwich

(Metal/Oxide/Semiconductor). The membrane and the base plate,

both made out of silicon, are then fused together on the

outside periphery, forming a mechanical and electrical

entity.

Both sides of membrane and the

silicon base plate of this measuring cell (the cavity),

are covered with an isolating layer of silicon oxide (SiO2),

over which the measuring electrodes are placed,

surrounded all around by silicon. The conducting silicon

builds a Faraday Cage around the measuring electrodes.

Upon request, the outside surface of the silicon could

also be coated to protect against aggressive environment. Both sides of membrane and the

silicon base plate of this measuring cell (the cavity),

are covered with an isolating layer of silicon oxide (SiO2),

over which the measuring electrodes are placed,

surrounded all around by silicon. The conducting silicon

builds a Faraday Cage around the measuring electrodes.

Upon request, the outside surface of the silicon could

also be coated to protect against aggressive environment.

The lateral dimensions of the

Sensor are 0,17 inch x 0,20 inch (4,32 mm x 5,08 mm). The total

thickness is 0,056 inch (1,4 mm). Electrodes are placed

in an etched chamber isolated from the silicon. The distance

between the measuring electrodes is 0,0002 inch (5 µm) this will yield a starting

Capacitance "Cx0" of 5 pF. The max

deflection of the measuring electrodes, due to the

loading of the membrane will be less than 0,0002 inch,

therefore a displacement free measurement is guarantied.

By changing the membrane thickness, a measuring range

between < 0,15 PSI to 2200 PSI

(<10 mbar to 1500 bar) could be achieved. The lateral dimensions of the

Sensor are 0,17 inch x 0,20 inch (4,32 mm x 5,08 mm). The total

thickness is 0,056 inch (1,4 mm). Electrodes are placed

in an etched chamber isolated from the silicon. The distance

between the measuring electrodes is 0,0002 inch (5 µm) this will yield a starting

Capacitance "Cx0" of 5 pF. The max

deflection of the measuring electrodes, due to the

loading of the membrane will be less than 0,0002 inch,

therefore a displacement free measurement is guarantied.

By changing the membrane thickness, a measuring range

between < 0,15 PSI to 2200 PSI

(<10 mbar to 1500 bar) could be achieved.

The measuring electrodes are

routed to the outside through the opening between the

membrane and the base silicon plate, where both the

electrodes and the shielded silicon are contacted with

two 0,012 inch (0,3 mm) thick coax cables (three-wires

version). It is also possible to connect the sensor with

coax cable (two-wires version), where the measuring

electrode and the silicon are shorted together. By

comparison, the three wire version, offers a higher

resolution and accuracy at a higher price. The measuring electrodes are

routed to the outside through the opening between the

membrane and the base silicon plate, where both the

electrodes and the shielded silicon are contacted with

two 0,012 inch (0,3 mm) thick coax cables (three-wires

version). It is also possible to connect the sensor with

coax cable (two-wires version), where the measuring

electrode and the silicon are shorted together. By

comparison, the three wire version, offers a higher

resolution and accuracy at a higher price.

The max resolution

at the moment stands at 0,002% of the max measuring

range.

Through the opening, the chamber

between the two electrodes is exposed to the surrounding

pressure, therefore it acts as a Relative

Pressure Sensor.

An Absolute

Pressure Sensor could

also be built by evacuating the chamber and hermetically

sealing the opening with Solder under vacuum (under

development). Through the opening, the chamber

between the two electrodes is exposed to the surrounding

pressure, therefore it acts as a Relative

Pressure Sensor.

An Absolute

Pressure Sensor could

also be built by evacuating the chamber and hermetically

sealing the opening with Solder under vacuum (under

development).

The sensor response is solely

dependent upon its mechanical construction. The measuring

cell itself is not linear. By increasing the pressure

this non-linearity will increase. However if the cell

membrane is deflected only to 60%, the error in linearity

will stay less than 1%. The sensor response is solely

dependent upon its mechanical construction. The measuring

cell itself is not linear. By increasing the pressure

this non-linearity will increase. However if the cell

membrane is deflected only to 60%, the error in linearity

will stay less than 1%.

No temperature dependant

"semi-conductor effect" will happen in the

sensor itself, because the silicon is used as a unitized

crystal and not as a P-N- Conductor. The eventual

temperature changes will only be due to the thermal

stress coefficient. Therefor in most applications , no

temperature compensation is necessary (temperaturecoefficient is less than

0,01 % / Kelvin). And service

temperatures are possible to 350 °C. No temperature dependant

"semi-conductor effect" will happen in the

sensor itself, because the silicon is used as a unitized

crystal and not as a P-N- Conductor. The eventual

temperature changes will only be due to the thermal

stress coefficient. Therefor in most applications , no

temperature compensation is necessary (temperaturecoefficient is less than

0,01 % / Kelvin). And service

temperatures are possible to 350 °C.

The world wide patented sensor

with integrated Faraday Cage, is a product of

many years of trials, before we were able to produce it

in series. (under license) The world wide patented sensor

with integrated Faraday Cage, is a product of

many years of trials, before we were able to produce it

in series. (under license)

By using the principle of a

Capacitive sensor, low power electronics can be used for

measurement By using the principle of a

Capacitive sensor, low power electronics can be used for

measurement

|